The synchronization between specifications and the PP master data is carried out via the general synchronization setting in the QPPD. In APP PP, a synchronization model is maintained for this purpose in which the mapping for

Specification types

Position types

Object types

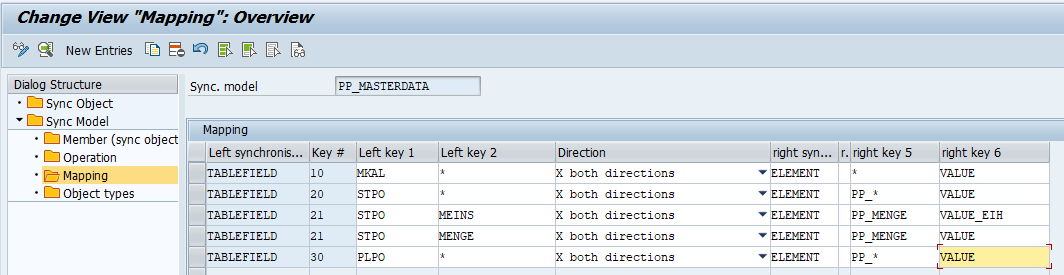

and the table field Mapping to the element for table MKAL, STPO, and PLP

are stored.

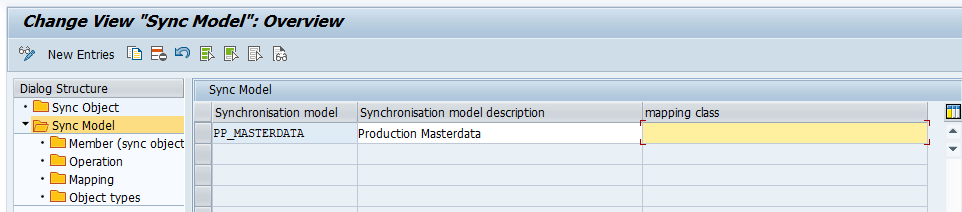

The default synchronization model for PP master data is PP_MASTERDATA.

The following steps must be executed

1. The initial creation of the synchronization model

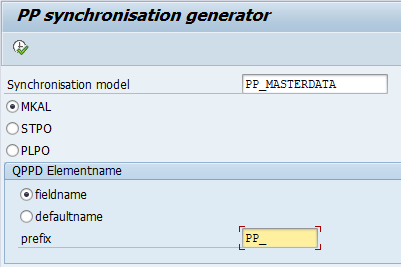

The initial creation is supported by the report /SCT/QP_PP_GENSYNC:

Examples of specification types, item types, and object types are created for the specified model. In addition, the table field mapping to the element is stored with the specified information.

The element name can be the same as the field name of the table or the default component name is selected. The default name is usually stored in the data elements of the fields as an English term. In addition, a prefix can be preset for the element name.

The program should be started for each table MKAL, STPO, and PLPO.

If other or further synchronization models are used, the variable MV_SYNCMODEL must be redefined in the /SCT/QP_CL_BAPI_PP class. The other synchronization model must then be specified when calling the interface methods.

The created data is not transferred to a transport request. The setting must be included manually in a transport request.

The maintenance of the synchronization model is done in transaction /SCT/QP_CUST → Synchronization or /SCT/QP_C70

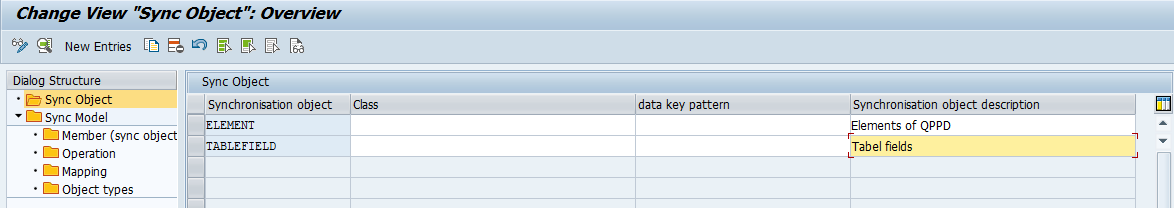

2. Synchronization Sync Object

3. Sync Model

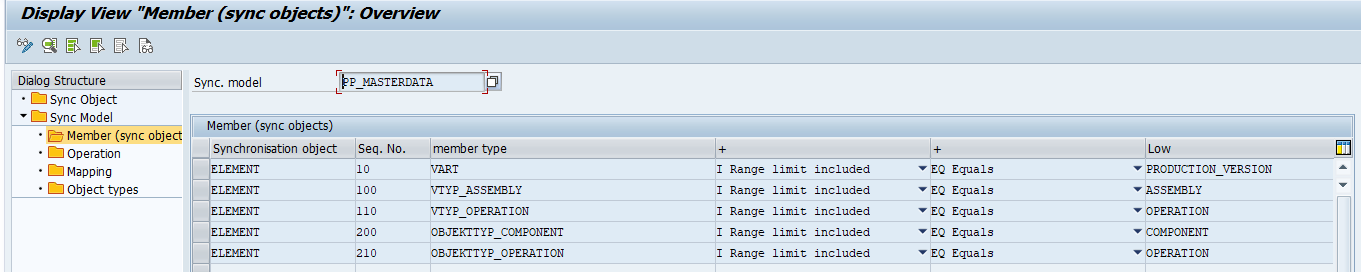

4. Sync Member

Meaning of member type:

VART: Defines the specification types that contain PP master data and are used when generating BOMs and routings.

VTYP_ASSEMBLY: Defines the item types that retain assembly information, assembly material and plant, and the components used. This setting is only needed if an instruction contains multiple assembly levels. Alternatively, the header node of the rule is used.

VTYP_OPERATION: Defines the item types that contain operations.

OBJECTTYPE_COMPONENT: Defines the tab where the components of the assembly are assigned.

OBJECTTYPE_OPERATION: Defines the tab where the default values of the operation are assigned.

5. Sync Mapping

For table fields, the mapping to the element and field is specified.

If the field name is equal to the element + prefix, this is only created by a default record. The field name is assigned with * and the element name with (prefix)*.