Variant configuration of the production route

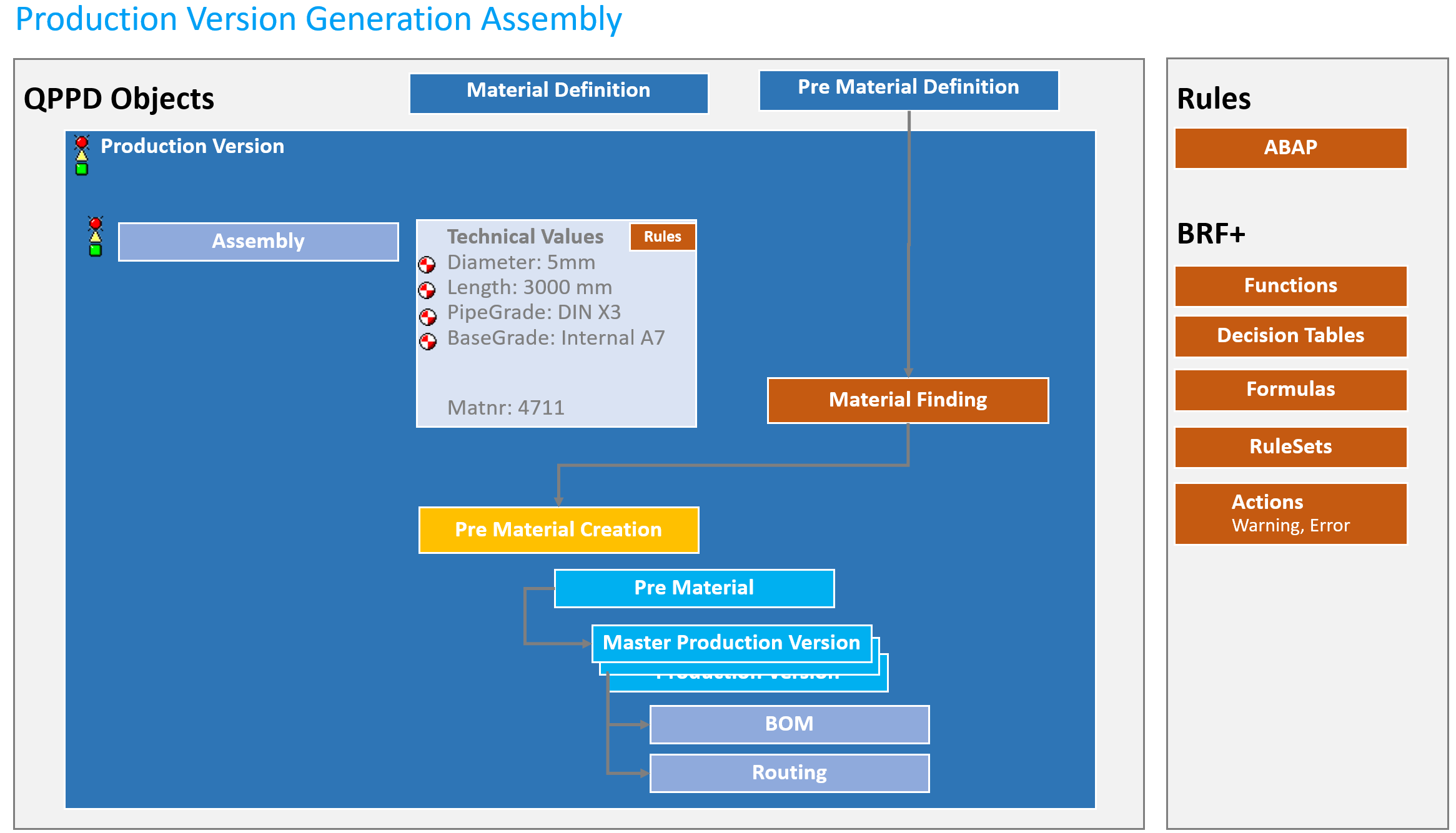

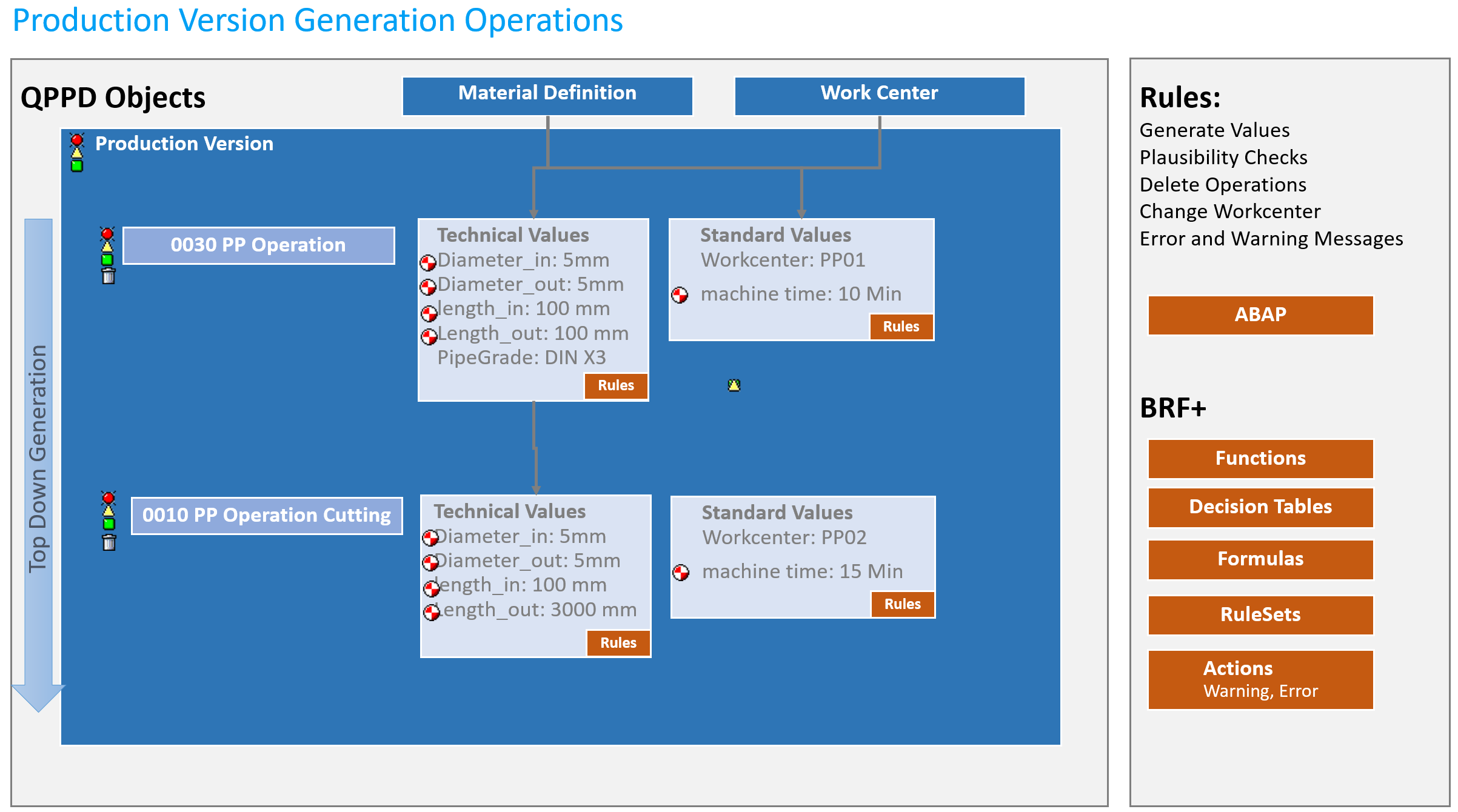

Bill of materials and operations, required for production order processing are determined based on technical specifications. An individual set of rules is used to generate the entire production route with its production alternatives. Changes to technical parameters and their effects on components and work processes can be simulated. The elaboration is available both in the customer order and in the material master.

Dynamical generation of BOM and routing for costing production order and planned order

In the standard SAP system, BOMs and routings are usually generated dynamically using object dependencies in variant configuration. The BOMs and routings are used for costing, planned orders, and production order generation. Material requirements planning also uses these dynamically generated objects.

With this APP it is possible to control the generation of BOMs and routings based on data from QPPD objects. The use of multi-level BOMs and their explosion is supported.

Maintenance of technical parameters and business rules in production order

A QPPD specification is integrated in the production order. Changing production-relevant parameters or confirmation of actual values, operations, and component quantities are determined by the current situation.