Metal Solution

Efficiency, quality and a head start for the metal industry

Complex requirements of the metal industry

The metal industry operates in an environment that goes far beyond standard ERP processes. Materials are rarely simple catalog products – they are defined by complex properties such as chemical compositions, mechanical strength or tight tolerance specifications. Added to this are individual customer requirements for packaging, labeling or testing, which must be precisely taken into account in every order.

Different business models face different challenges:

Manufacturing plants have to control complex metallurgical production processes from crude steel to the finished product – from melting and rolling processes to special heat treatments. Service centers focus on the efficient procurement, warehousing and further processing of commercial materials with flexible processing capacities such as cutting, bending or surface treatment.

Processes in for SAP S/4HANA® already form a powerful basis for this. However, it becomes evident that additional support is particularly helpful in the metal industry.

We have gained our experience through many industry-specific customer projects and have developed a “best practice” metal solution as a result. This solution is tailored to the requirements of the metal industry and covers the needs of both service centers and manufacturing plants.

The QPPD framework integrates seamlessly into existing SAP systems. It specifically extends the standard with additional data and functionalities and increases the degree of process automation.

Master data management

With QPPD, master data can be managed centrally and in a structured manner. Individual data structures can be flexibly mapped and directly linked to each other – for example material standards with matching tolerance standards. This creates a consistent database (“single source of truth”) that can be used in all areas of the company.

Read more

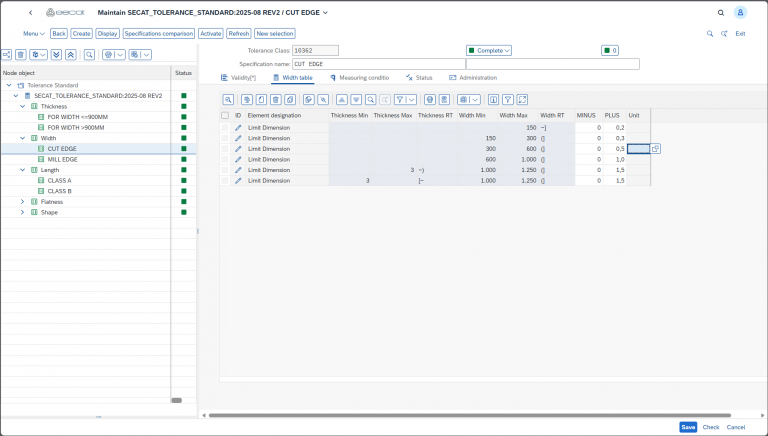

Master data can be managed with QPPD. The QPPD Object Designer enables the modeling of individual data structures, allowing for a solution that is precisely tailored to the needs of each company. It is also possible to link the corresponding objects directly. For example, material standards can contain a link to a separate tolerance standard object.

Status and versioning concepts ensure clean and traceable data management. As all master data can be linked with each other, a single source of truth is created that provides consistent product data for all areas of the company.

Combined with the BRF+ framework, business rules can be defined directly by the business users — eliminating the need for IT involvement. This enables data validation, automatic assignment of default values, and even complex calculations — for example, chemical analysis formulas. This significantly increases the quality and reliability of data storage.

By integrating with sales, production, purchasing, and quality management, even the most complex product information can be mapped in a structured and consistent way. This provides transparency into product complexity and makes it controllable across all processes.

Our Metal Solution provides a predefined data model based on our many years of experience in the metal industry. It is designed in such a way that it already comprehensively depicts the typical structures and characteristics of metal products. This allows industry-specific requirements to be taken into account directly.

Included are for example:

Material standards with chemical and mechanical/technological properties

Tolerance standards for every material geometry

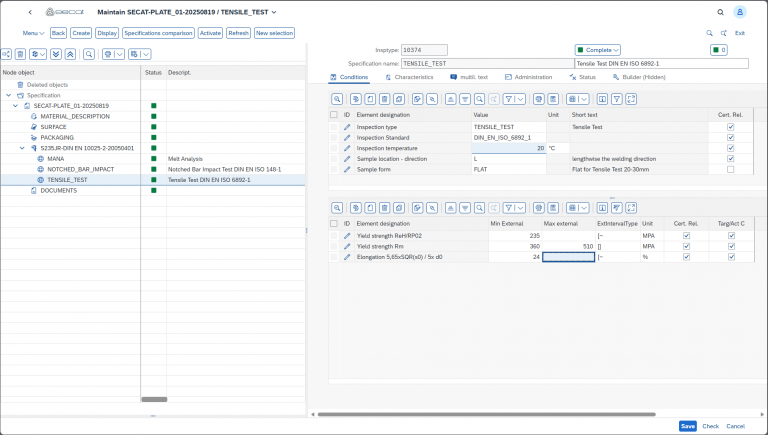

Quality inspections that clearly separate and account for testing conditions and inspection criteria.

Production parameters that enrich the corresponding production versions

Another important object in the Metal Solution data model is the customer specification. It makes it possible to present the individual requirements of customers in the metal industry clearly and comprehensibly. Whether packaging, labeling, price-relevant properties or quality-related inspection values – all information is maintained centrally.

Direct QM integration has also been implemented so that the inspection processes with inspection characteristics can flow directly into inspection plans or thus also directly into the inspection lot. Redundancies are minimized, as dimension-dependent material properties can be completely captured within a single specification.

The outcome is a consistent, end-to-end process chain — covering everything from product definition and quotation to order processing, costing, production, quality inspections, and certificate issuance.

Material master integration

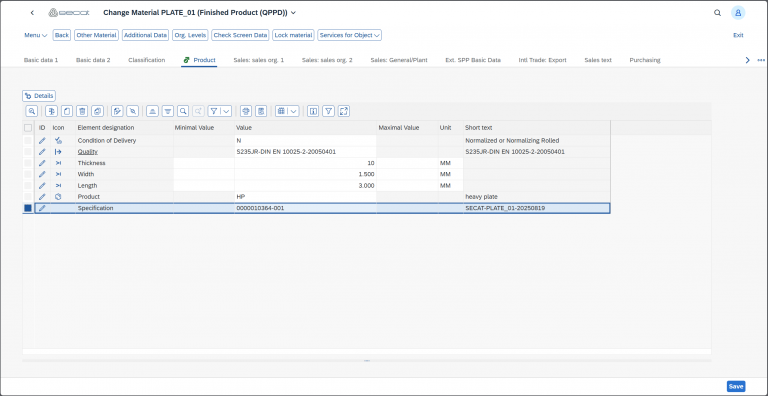

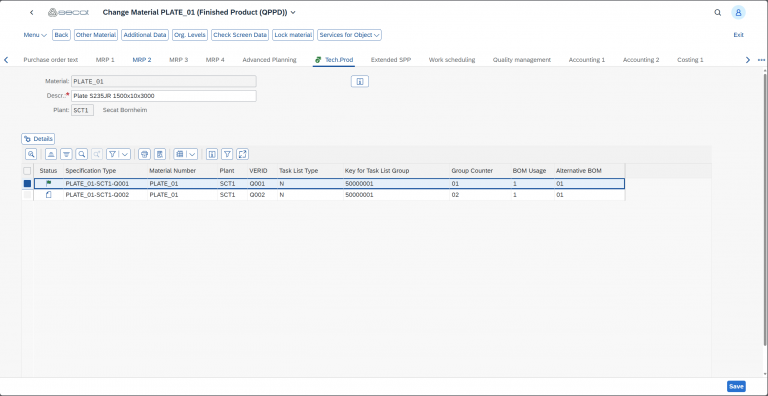

Expand your SAP material master with QPPD functionalities using two specialized views. The product view links the material with basic material properties in the form of specifications and tolerance standards, for example, while the production view manages plant-specific production versions with detailed parameters.

Read more

The material master remains the central backbone of your SAP system and is considerably enhanced by the seamless integration of QPPD without affecting the familiar way of working. Two specially developed QPPD views make it possible to link materials with master data.

Product view for material properties: The basic characteristics of your materials are systematically recorded and managed in the product view. Here you can store specifications that not only describe the direct material properties, but also contain references to other relevant master data. For example, tolerance standards, material standards or quality standards can be linked directly, creating a complete picture of the material requirements. This structured data linking forms the foundation for consistent product information across all areas of the company.

Production view for production control: The production view focuses on plant-specific production and enables detailed control of production processes. Multiple production versions can be defined and managed for each material, each enriched with specific production parameters. This takes into account different production processes, machine equipment or qualitative requirements of different plants. The production parameters include not only process settings, but also quality specifications, inspection intervals and plant-specific standards.

This two-part integration keeps the complexity manageable for the user, while at the same time providing the full flexibility of QPPD. Production planners receive all the information they need for optimum production control, while product developers and quality managers can access detailed material properties and specifications.

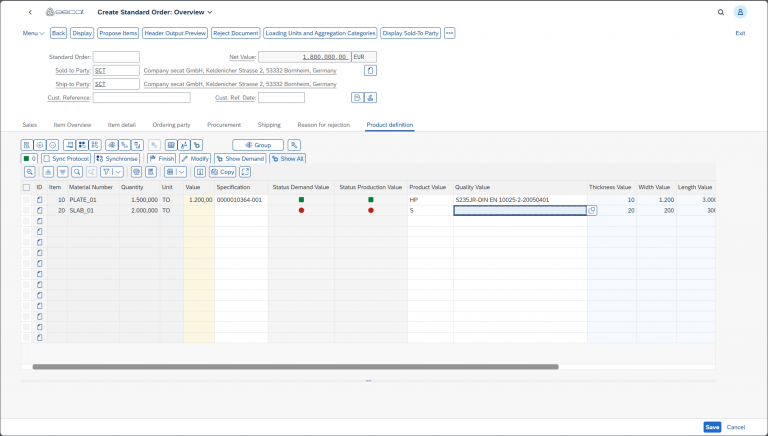

Sales processes

The Metal Solution adds practical functions to SAP sales processes. Customer requirements are recorded centrally, versioned transparently and can be used consistently right through to pricing and calculation. This creates an efficient, consistent and transparent sales process.

Read more

The Metal Solution fully integrates QPPD into all relevant sales documents – from quotations and contracts to orders. A demand specification is stored for each sales item, which records all customer requirements centrally. No limits are imposed on the variety of product-describing characteristics. Even product descriptions with 2,000 characteristics can be managed.

The associated versioning of the demand specification ensures that changes are documented at all times and can be tracked transparently even during ongoing orders.

A fast data maintenance function is also available for simple or recurring requirements. This allows changes to be made directly in the sales document.

In addition to these basic functions, QPPD extends the standard SAP processes in sales with practical additional functions:

Product definition: Determination/calculation of product data based on customer specifications and standards, also in combination with variant configuration

Evaluation of customer requirements: Inputs are continuously checked for consistency and plausibility using BRF+ rules

Pricing: Product features flow directly into pricing.

Error handling: Status concepts enable structured processing of sales items and ensure clean processes.

Simulation and calculation: Production data derived from the product definition can be used directly in simulations, enabling reliable calculations within the sales process.

The close linking of product and production data creates a high level of transparency throughout the entire sales process. Decisions are based on consistent information from the processes themselves. This enables precise calculations and well-founded quotation arguments.

It also offers great added value for the business model of service centers:

The Service Center business is primarily based on the sale of stock items that require reworking based on customer requirements.

Practical example: A stock material requires further production steps such as a cutting operation and external subcontracting for surface treatment.

In the demand specification, the set of rules calculates the dimensions and serves as the guideline for the cutting process.

A supplier selection with price information can be made directly for subcontracting.

Based on this, a production version is generated and used directly in the calculation. The calculated costs can be taken into account in pricing.

The certificates of conformity of the stock material are directly linked to the requirement specification.

Production order

QPPD enables a dynamic response to production events directly in the production order. Technical parameters are visible and adjustable — changes, such as a machine swap, can be easily tracked in the production order and can automatically propagate adjustments to all affected operations and components without manual effort.

Read more

Practical example of a machine change: A typical scenario illustrates the efficiency: If, for example, a small press needs to be changed to a large press, this change can be made directly in the corresponding production version of the production order. The system then automatically adjusts all affected production parameters, process times and material components – without manual intervention or additional planning effort. This also includes the adjustment of set-up times, throughput times and any changes to the material composition or specification.

Complete transparency and traceability: All technical parameters remain visible and comprehensibly documented throughout the entire production process. This not only enables precise control and monitoring in real time, but also complete traceability of all changes and decisions. Even spontaneous changes in the production process can be flexibly monitored and documented at any time.

Advantages for production control: Direct integration ensures a seamless connection between planning and execution. Production managers and machine operators always have access to the latest parameters and can make informed decisions. At the same time, quality managers are automatically informed of relevant changes that could have an impact on inspection programs or quality standards.

Production engineering

The Metal Solution supports the definition of individual metal products and ensures that production is carried out exactly according to the specified parameters. Work plans, parts lists and production parameters are automatically combined into a suitable production version – precisely tailored to customer requirements.

Read more

When manufacturing individual metal products, the focus is on product definition with all product-describing parameters. Production must then be controlled in such a way that the customer receives exactly the product that was defined. This means that the technical process must be derived on this basis.

Various important questions arise directly from this:

On which work centers can or must I manufacture the product?

Which production parameters need to be set so that I can achieve the desired material properties?

Which components do I need to create my product?

What are the costs for different possible production versions?

In this context as well, the Metal Solution already provides a basic approach to optimize these processes:

Work plans, parts lists and production parameters automatically generate the appropriate production version – precisely tailored to customer requirements.

Production and inspection processes are mixed directly with each other and displayed in the corresponding production version → Direct QM integration in the production order

BRF+ rules can be used to reliably automate scrap calculations and feasibility checks

The production versions generated with QPPD are used in the product costing, MRP run and production and inspection planning processes.

Integration into purchasing

The Metal Solution integrates the structured QPPD database directly into the procurement process. All relevant product properties, production specifications and inspection standards are consistently available in purchasing and can be automatically inserted into order texts – without manual input.

Read more

The integration of QPPD into the purchasing process creates a continuous information chain from product definition to procurement. Thanks to the direct connection to the structured qppd database, all relevant information is consistently and immediately available in purchasing and can be flexibly adapted as required.

Procurement of primary materials: When ordering primary materials, the order is automatically enriched with all the necessary product properties. This includes, for example, the chemical analysis with the required element contents and tolerances, mechanical characteristics such as tensile strength or hardness, precise dimensional data and other material-specific requirements. The purchaser no longer has to research these specifications manually or collect them from various documents – they are available directly from the linked material master.

Purchased contract processing: Production specifications and pricing information can be seamlessly integrated for outsourced processing steps. This includes detailed production parameters, quality specifications, tolerance requirements and the agreed conditions for the respective process. In this way, the supplier receives all the necessary information for precise execution, while the purchasing department retains cost transparency at the same time.

External testing and quality inspections: When placing test orders with external laboratories, test standards, sample forms, test conditions or other specific specifications can be taken directly from QPPD. This ensures that the inspections are carried out exactly according to the defined standards and that the results are directly comparable with the internal requirements.

Automatic order text creation: All available additional information from QPPD can be automatically inserted into the order texts. This is done either using predefined text modules or intelligent rules that compile the relevant information based on the material parameters. This completely eliminates time-consuming manual input and sources of error due to typing errors or outdated information.

Efficiency gains and transparency: This integration makes the entire purchasing process considerably more efficient and transparent. Buyers can concentrate on strategic tasks such as supplier negotiations and evaluations instead of spending time compiling technical specifications. At the same time, the quality of procurement processes is increased as all requirements are communicated completely, correctly and up to date. This leads to fewer queries, reduced rework and improved supplier performance.

Quality management

The Metal Solution seamlessly integrates QPPD into the inspection lot processing. Inspection operations are created automatically from the demand specification and production version. Alternatively, CAQ (Computer Aided Quality) integration enables the direct exchange of target specifications and actual results for consistent quality assurance.

Read more

The integration of QPPD into quality inspection and inspection lot processing creates a continuous link between product definition, production and quality assurance. The Metal Solution supports both classic SAP inspection lot processing and integration with modern CAQ systems in order to offer maximum flexibility for different system landscapes.

Automated inspection lot creation: When creating inspection lots, the inspection operations and inspection specifications are no longer defined manually, but are generated automatically based on the stored requirements specification and the active production version. This ensures that all relevant inspection characteristics are taken into account and that the inspections correspond exactly to the requirements of both the product and the selected manufacturing process. Changes to the specifications or production parameters are automatically reflected in the inspection planning, ensuring that it remains up to date.

CAQ system integration as an alternative: For companies that use external CAQ systems, the Metal Template offers a powerful alternative solution to the classic inspection lot. In this scenario, the target values for inspection characteristics are transferred directly from the demand specification and production version to the CAQ system. This enables seamless use of the specialized functionalities of the CAQ system, while at the same time maintaining QPPD ‘s central database as a single source of truth.

Bidirectional data exchange: The actual inspection results from the CAQ system are automatically written back to QPPD inspection points. This bidirectional data exchange ensures that all quality information is available centrally and can be used for downstream processes. The inspection results are thus directly linked to the production data, material masters and customer orders, which enables seamless traceability.

Flexible certificate of conformity creation: Both the classic SAP inspection lots and the QPPD inspection points from the CAQ integration are available for automated certificate creation. This provides maximum flexibility in system design, allowing companies to make optimal use of their existing infrastructure without sacrificing the benefits of end-to-end quality documentation. The certificates of conformity contain all the necessary inspection results and can be configured according to customer requirements.

Quality benefits and compliance: Automated inspection planning and end-to-end data integration significantly increase the quality of inspections. Manual errors in the inspection definition are eliminated, all normative requirements are systematically taken into account and documentation is complete and traceable. This not only facilitates internal audits, but also the fulfillment of customer requirements and regulatory specifications such as ISO 9001 or industry-specific certifications.

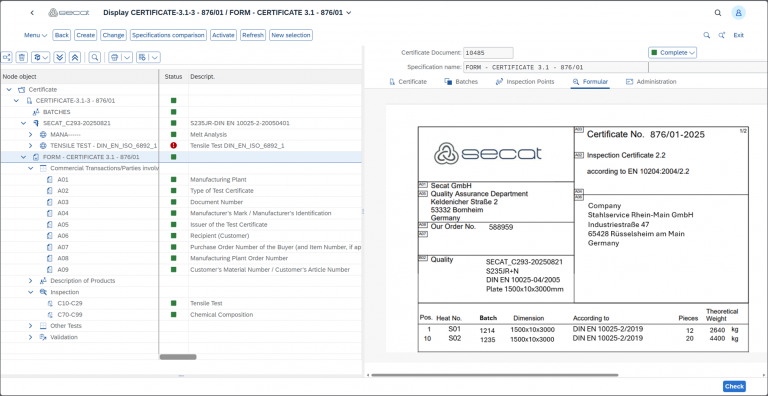

Certificates of Conformity

With QPPD, certificates of conformity can be created automatically and fully integrated – from data collection and approval to PDF generation and dispatch. This allows customer-specific certificates to be created quickly, transparently and in multiple languages.

Read more

QPPD provides a fully integrated creation of certificates of conformity. A QPPD certificate specification is created based on a delivery or by manual triggering for preliminary certificates or third-party approvals.

The following functions are carried out automatically in the certificate document:

Data determination: The document collects all relevant data from inspection lots, customer orders, batches and demand specifications.

Release: The integrated target/actual comparison in the certificate ensures that all specifications are met and correctly documented.

The automatic system is interrupted in the event of negative usage decisions. Manual special releases are necessary.

If external acceptance is required (3.2 certificate of conformity), a preliminary certificate is generated and the results are taken into account during release

Form creation: The associated layout object defines the arrangement of the content in the final PDF and can be configured with little effort. This automatically creates customer-specific certificates with different content. The system supports multiple languages so that international customers automatically receive certificates in their desired language.

Output: An integrated email control ensures that the form is sent. An EDI connection can be integrated.

Material passport: The translation of target and actual values into a digital material passport is fully supported. This means that the certificate can also be used for holistic digital processes.

Versioning and change management: All certificates can be versioned and changes can be integrated quickly and comprehensibly.

The certificate cockpit provides an overview of certificate documents with extensive filter options. It is immediately apparent which certificates are still incorrect or incomplete.

Ready for use in your company?

The Metal Solution already represents a best-practice solution: The predefined database means that central requirements for handling quality and production data are covered right from the start. In addition, the solution not only provides structures, but also the associated processes that can be used immediately.

At the same time, the solution remains flexible. It can be expanded and adapted to specific requirements at any time. This is where QPPD’s agile approach comes into play: it is not necessary to define all the details in advance. New requirements can be implemented step by step and integrated seamlessly.

This means that companies benefit immediately from a ready-to-use industry solution and at the same time retain the option of dynamically developing their systems further.

Do you have any questions or require further information?

Contact us – we will be happy to show you the Metal Solution in a live demo and develop the next step for your company together.